150,000 m

Drilling Completed

63 Veins Open Along

Strike and at Depth

Shallow Resource from

Surface to 700 m Depth

96% Average

Metallurgical

Recovery 65% Free Gold

Clear Pathway

to beyond 5 Moz+ Au

47 Historic Gold

Occurrences on 33 km Trend

Consolidated

100% Owned 14,000 ha

Brownfields Camp

Mineralization

Confirmed

to 2 km Depth

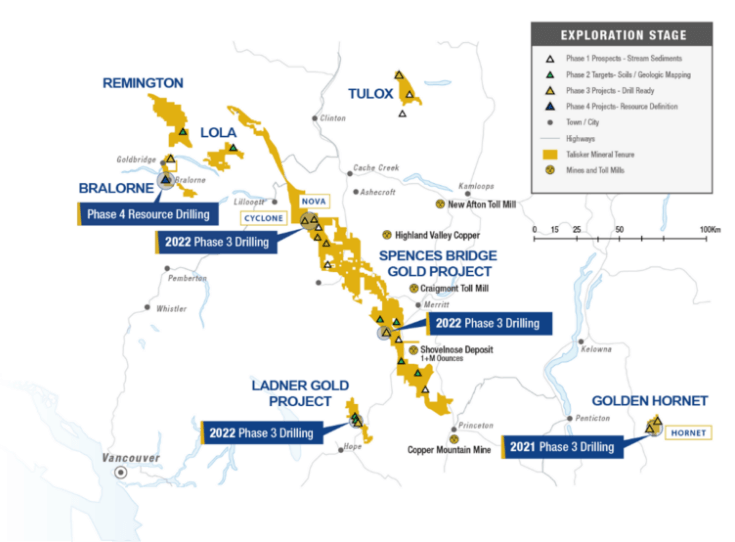

The Bralorne project is supported by significant infrastructure with direct highway access, grid connected electricity, permitted tailing storage facility, water treatment facilities, offices, mill building, underground workshop, mine dry, core logging, processing and storage, bunkhouse, kitchen, ambulance and mine safety, and industrial fuel storage facilities.

ACCESS

Easily accessible by car from Vancouver, Bralorne can be reached either via Lillooet (Highway 40, 371 kilometres) or via the Hurley Pass (231 kilometres) with Highway 40 maintained by the BC Government providing year-round access.

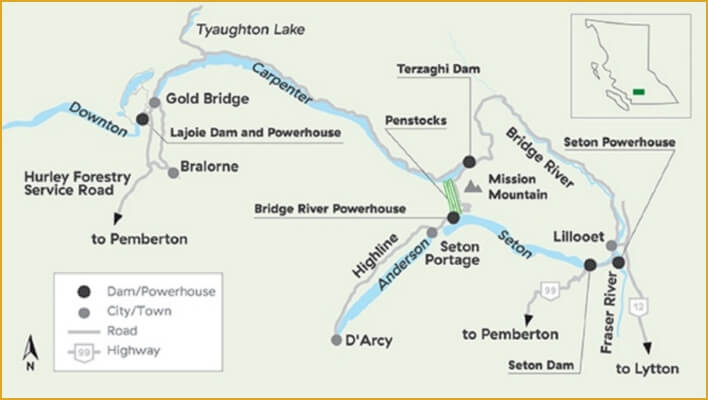

Grid Power

The Bralorne site is connected directly to grid power with a 1500kva line from the Lajoie Hydro generation plant just 4 kilometres direct line from the site. The Lajoie dam and plant is part of the Bridge River hydroelectric complex that has capacity to generate 492 megawatts of power.

Tailings Storage Facility

The Tailings Storage Facility (TSF) is permitted under the existing mine permit. The tailings and water ponds are contained within a footprint area of approximately 4 hectares. The combined area of disturbance including TSF, dam, seepage ponds, borrow areas, and topsoil stockpile is approximately 10 ha. The volume currently available within the TSF is estimated at 126,000m3 or approximately 170,000 tonnes of tailings (average settled dry density of 1.35 tonnes/m3). The current permitted area would allow for significant increase in storage capacity.

State Of The Art Water Treatment Facility

The Bralorne site has a fully permitted and operational water treatment facility. The current facility was commissioned on April 1, 2016 and consists of a modular PALL Aria microfiltration system. The system is actively used to treat mine discharge and mine water from the current dewatering program. Under Discharge Permit 14480, treated water can be discharged continuously to Cadwaller Creek at a rate of 3 million litres per day. Additional water is permitted to be discharged to the Tailings Storage Facility. Sludge from the microfiltration system is contained in geotubes, which are then transported to a storage location in the tailings facility for permanent storage.